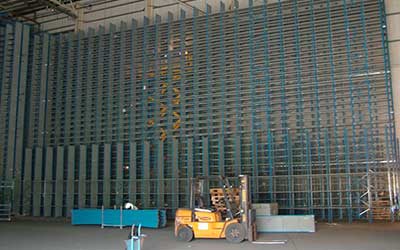

Pallet Racking systems are a highly efficient form of Rack, designed to hold palletised goods in many possible configurations, but always maximising the use of available volume within a storage venue .

Each Pallet Racking system that Space Age Storage UK Ltd supplies and installs is a bespoke solution tailored to the specific needs of the client. We operate our own installation and dismantling teams, who have many years of combined experience in erecting and dismantling pallet racking based storage systems.

A selection of the pallet racking solutions that space age storage can supply include:

- Standard Adjustable Pallet Racking – Normally installed with wider aisles (3 metres wide +) to suit a small counterbalance type fork lift truck.

- Narrow Aisle Racking – With aisles typically between 2.1 metres and 2.5 metres wide, narrow aisle systems utilise special narrow aisle type fork lift systems which are often wire guided or which use guide rails to steer the

- Very Narrow Aisle Racking – With aisles typically below 2.1 metres wide, VNA systems utilise special narrow aisle type fork lift systems which are often wire guided or which use guide rails to steer the truck.

- Push-Back Pallet Racking – This is a dynamic form of pallet racking which stores several pallets deep on each storage level. Pallets are located on a set of nested push back sleds which are in turn located on a slightly inclined set of rails. Pallet 1 is located on the front sled. Subsequent pallets push back the leading sled and are deposited on the sled immediately behind the first. When a pallet is retrieved, the pallet immediately behind, rolls slowly forward to thepick face.

- Drive-In Racking – This system is designed to maximize volume use in situations where many pallets of the same size and type are stored. The fork lift truck drives in to the rack by means of a set of nominated lanes and deposits pallets on to any one of several sets of rails which are pitched at the appropriate pallet heights. The racks can be constructed to take several pallets in the depth x several pallets in the height. This produces a very dense and efficient storage solution, although retrieval of pallets is limited. Front pallets must be removed prior to rear pallets becoming accessible for retrieval.

- Cantilever Racking – Designed to store long pallets or strip products, these racks are formed from connected sets of ground fixed vertical uprights, and large lock in load support arms. They are often used in conjunction with side loading fork lift trucks and bespoke slave pallets.

We already supply our bespoke pallet racking solutions to companies with a wide variety of storage needs, and all are Manufactured to BS EN ISO 9001 2000 by original equipment manufacturers.

Space Age Storage UK Ltd Pallet Racking

All of our Pallet racking systems are constructed for heavy duty use within an industrial environment and each installation is specifically designed to meet the individual needs of a clients operation.

Space Age Storage UK Ltd can also advise on specific equipment accessories such as heavy duty rafted decks, pallet support bars, rack protection barriers and guards and bespoke items such as drum storage chocks.

If you are unsure which type of Pallet Racking system you require or would like to match your existing racking system please click here to match your existing pallet racking against our chart of the 17 most common types currently available.

At Space Age Storage we stock a large selection of new and used pallet racking which includes the following makes:

- Dexion Speedlock

- HI-LO

- Redirack

- Link 51 XL

- Apex

- Finspa

- Stackapal

- Planned Storage

- BITO

- Gasgoine

- Mecalux

- Integrated Handling

- Electrolux

- Linpac Pallet Racking

- Polypal

- Acrow

- Birmingham Pallet

- Seco

- Bartrak

- and many more...