Crane Driven warehouse racking has been around along time and may be found in many forms. It is normally the preserve of ‘distribution centre’ type business models and is often integrated with pallet conveyors and sometimes even ‘AGV’s – or automatic guided vehicles’. Installations of this type cost many millions of pounds to build and commission yet at ‘end of life’, can be a substantial liability in the form of huge decommissioning costs…….with empty property sometimes attracting ongoing rates demands as a result of empty occupation, sometimes, the only choice is to decommission large installations.

To take down the cranes from inside a crane rack, you need a really powerful mobile crane. In this case, a Faun capable of lifting 13000kg (more than adequate for our purposes – envisaged load – up to 7000kg).

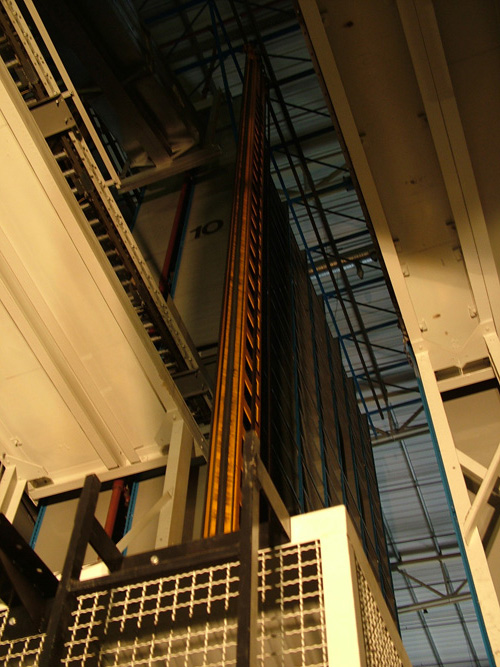

The racking that formed this phase of the installation is pictured below – it is a shelving based system of over 50ft in height and had to be dismantled by hand using special high reach scissor lifts – this took several weeks.

An interesting fact about mobile site cranes is that whilst ambling around the road networks, on their way to their respective projects, they may seem ungainly in the extreme; however when it comes to operating in their intended venue, they are one of the most tactile, sophisticated precise and controllable pieces of equipment in the market place. If you were to imagine focusing a manual microscope – this is the fineness of control available in a modern crane.

With extreme care, the warehouse crane is attached to the mobile crane using 2 steel hawsers each over an inch thick linked to the manufacturers lifting point. Then gradually, Kilo by Kilo, the mighty Faun takes up the weight until the warehouse crane floats just a couple of inches above its main guide rail…hanging in precision guided space.

Gradually the Crane begins to rotate on its base moving the immense warehouse crane from its dock, out in to the open space of the main warehouse before lying it down gently on the ground. The warehouse crane is then cut up in to small pieces and removed for recycling.

Detailed planning and the correct crane for the task are the prerequisites of a safe and successful crane lift.

A detailed site survey by both the crane company and our own project team will deliver data covering issues such as risk, anticipated method, local topography and specific site features all of which may affect the lift. The surveys will look carefully at the ground upon which the crane and its outrigger stabilisers will stand.

It is crucial that the ground under the crane is stable and strong enough to cope with the point loads that the stabiliser ground pads will impose. These can be considerable and so even heavy concrete floors must be surveyed and data acquired to show they are up to the task. A ground failure during a lift can be catastrophic so detailed due diligence is required.

The crane survey team will produce detailed calculations of predicted pad loads together with the planned radius of the lift area and will deliver all of this information in a form which meets both statutory health and safety and operational needs.

This will include a detailed risk assessment and method statement, copies of their insurances, crane certifications, operating licenses and other general documentation.

This will be added to our own risk and method statements to provide for a combined plan which covers every aspect of the process from the cranes arrival at site, to processing and removing the load from site at the end of the project.

Estimates of load weight are never left to chance – in this case, the manufacturer of the picking crane was contacted for guidance both for the load weight and for data on their lifting eye specifications.

As can be seen, much of the project is spent on the detailed planning cycle, after which, comes the final lifting operation. In this case, we lifted down and cut up seven 50ft high x 5000kg picking cranes in just 2 days.